Quality assurance

We believe quality should be a total team effort. This is a built in feature at NMA from design through the finished product, every step of the manufacturing process is carefully monitored. It takes more than superior engineering and equipment to make precision springs.

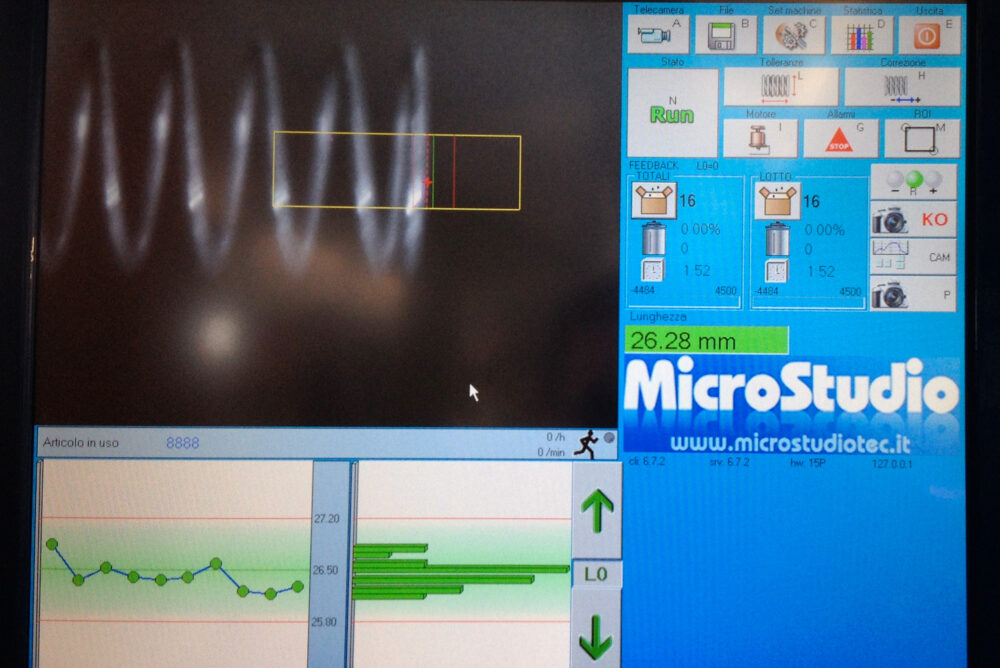

Constant monitoring of the manufacturing process is necessary to guarantee “part-to-part and order-to-order” uniformity. Prevention, not detection. We’ve been using SPC for years long before it became fashionable, and require the same of our material suppliers. This assures the quality of your spring both before and during manufacturing.

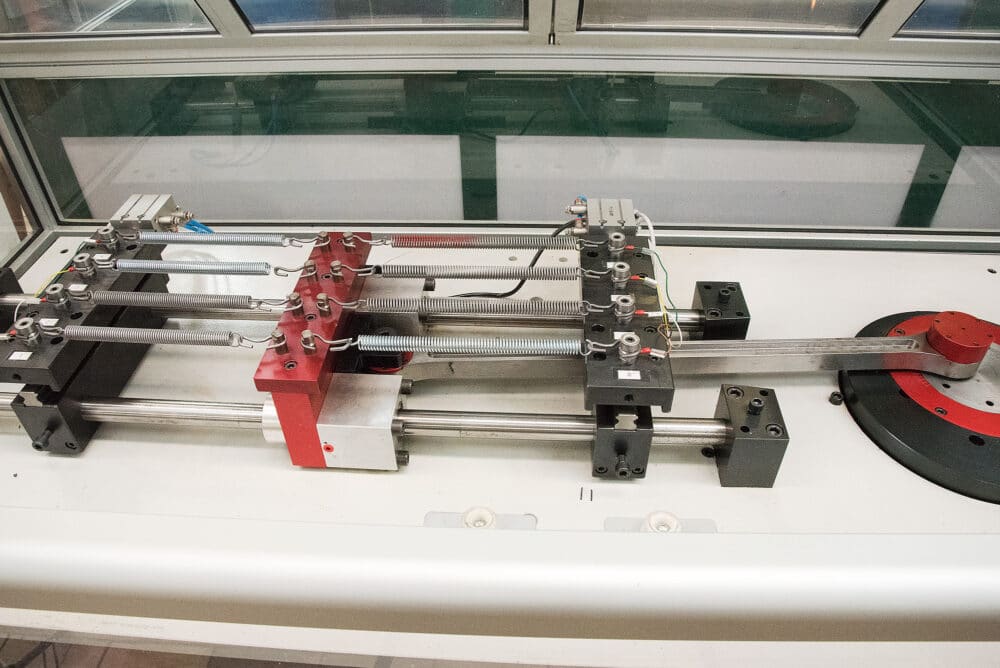

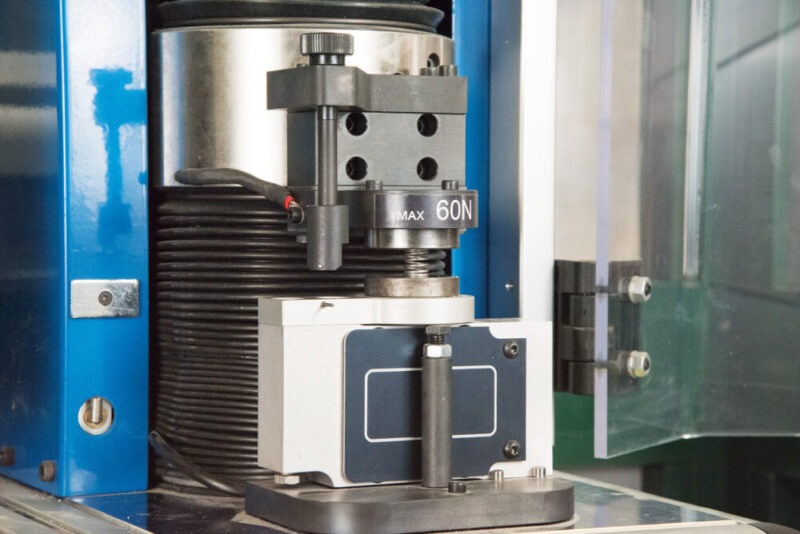

On-line testing using many state-of-the-art digital instruments and sophisticated software for evaluating stress, loads, and rates is complemented by rigorous final testing by our quality control department which is UNI EN ISO 9001:2008 Registered and certified by government agencies, as well as, many of the largest manufacturers in the country.

Spring design service and engineering

“We help you from the start”.

Our engineering staff can work with your design engineers from the start of your project. Our spring design assistance often proves invaluable as does our rapid prototyping.

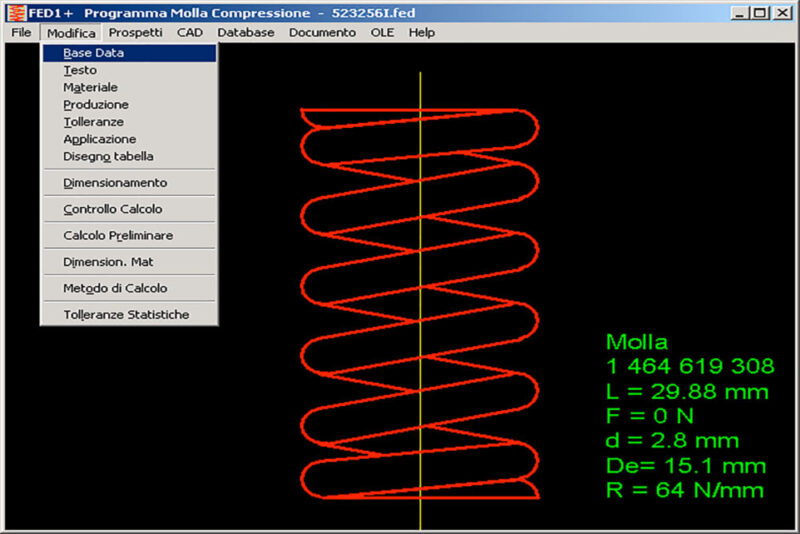

NMA has a genuine interest in solving the problems encountered by our clientele. The need for consultation and assistance when designing springs is fully recognised by us and we are able to provide on-site advice, or assist in specific project development in conjunction with the requirements of a design engineer. NMA engineering group has the technical expertise to provide customers with a wide range of supporting practices. Call us for design assistance. We offer a quick response to meet your needs from prototype springs to small batch springs to various high precision springs and high tech springs that require fast turn around. We pull the spring design information into our own proprietary computer program to analyze the spring design function, as well as, manufacturability.

No order is too small or too large! We will share our years of experience in thousands of different applications enhanced with the latest technology assuring you of receiving springs in the shortest possible time. From concept to completion your product gets to the market faster with the lowest amount of developmental costs.

We offer design assistance, custom-packaging and work tirelessly to manufacture springs which are 100% compliant to your specifications. Let us know how we can help you meet your project goals.

Check our services:

- Complete spring design capability;

- Rapid Prototyping;

- Computer aided design (CAD);

- Design modifications for cost efficient production;

- Alternative manufacturing and materials evaluation;

- Tooling designed and manufactured with minimal or no tooling charges;

- State-of-the-art coiling technology;

- Fourslide operations;

- Secondary capabilities;

- SPC and Quality Control;

- Special packaging;

- Compliance barcode labeling;

- Cost competitiveness;

- On-time delivery;

- Unsurpassed quality.